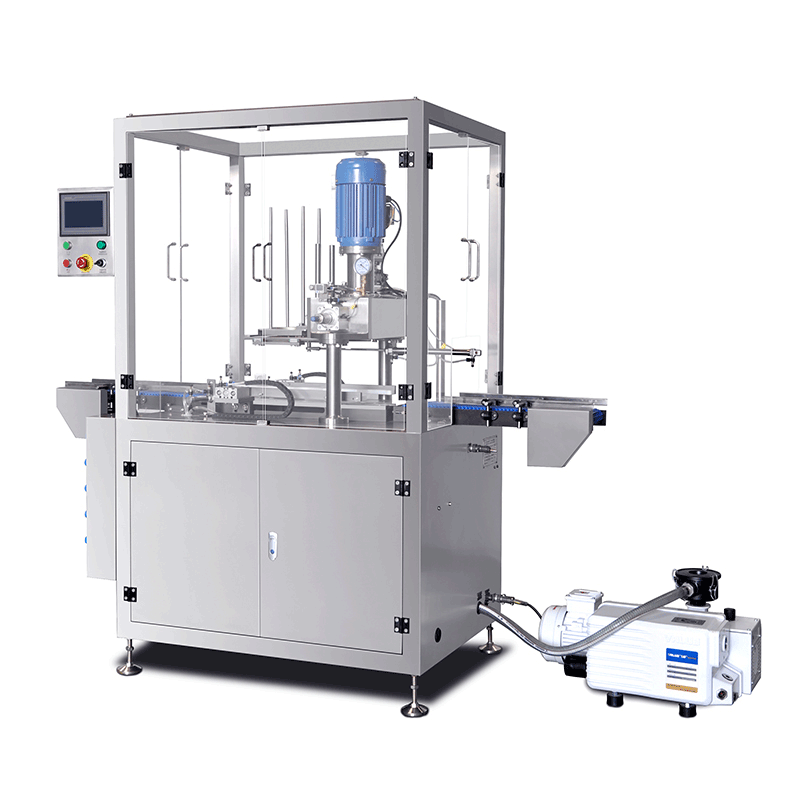

FGZK-A

Fully Automatic

- Speed: 6-7 cans/min

- Can Diameter: φ70-127mm

- Can Height: 60-190mm

- Voltage: Three-Phase 380V

- Power: 4.0 Kw

- Compressed Air: ≥0.6MPa (6Bar)

- Air Consumption: 200L/min [1]

- Nitrogen Pressure: ≥0.2MPa (2Bar)

- Nitrogen Consumption: 50L/min [1]

- Total Weight: 520 Kg

- Dimensions: L2100*W780*H1850 mm

FGZK-B

Semi Automatic

- Speed: 5-6 cans/min

- Can Diameter: φ70-127mm

- Can Height: 60-190mm

- Voltage: Three-Phase 380V

- Power: 3.3 Kw

- Compressed Air: ≥0.6MPa (6Bar)

- Air Consumption: 60L/min [1]

- Nitrogen Pressure: ≥0.2MPa (2Bar)

- Nitrogen Consumption: 50L/min [1]

- Total Weight: 350 Kg

- Dimensions: L800*W720*H1850 mm